hardness test for tablets|tensile strength vs hardness tablet : agency "Tablet hardness" is a measure of the force required to break a tablet in a test apparatus that places the tablet under a tension or bending load. The hardness of a tablet plays a crucial role . web22K Followers, 7,458 Following, 1,378 Posts - See Instagram photos and videos from Século Adega (@seculoadega)

{plog:ftitle_list}

webSe connecter. Mot de passe oublié ? Créer un compte. Créer une Page pour une célébrité, une marque ou une entreprise. Connectez-vous à Facebook pour commencer à partager .

tensile strength vs hardness tablet

water vapor permeability test solution

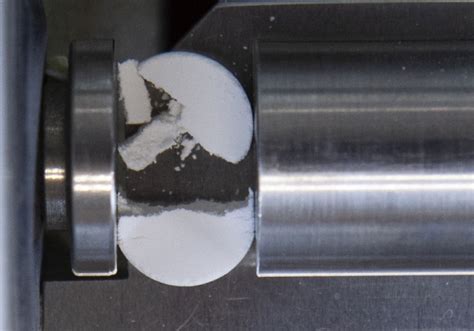

Hardness and friability are important physical parameters for a tablet. These parameters ensure the strength and structural integrity of a tablet for transportation, packaging and handling before usage."Tablet hardness" is a measure of the force required to break a tablet in a test apparatus that places the tablet under a tension or bending load. The hardness of a tablet plays a crucial role . Tablet hardness testing makes sure that solid tablets are hard enough to sustain mechanical strains during various situations like storage and packaging, delivery and handling .Tablet hardness testing is a laboratory technique used by the pharmaceutical industry to determine the breaking point and structural integrity of a tablet and find out how it changes "under conditions of storage, transportation, packaging and handling before usage" The breaking point of a tablet is based on its shape. It is similar to friability testing, but they are not the same thing. Tablet hardness testers first appeared in the 1930s. In the 1950s, the Strong-Cobb tester was in.

Tablet hardness refers to the ability of a tablet core to withstand tumbling in a coating pan, typically measured using a tablet hardness tester in units such as kiloponds, Strong Cobb .

The breaking force of tablets is commonly called hardness in the pharmaceutical literature; however, the use of this term is misleading. In material science, the term hardness refers to the resistance of a surface to penetration or indentation by a small probe. The term crushing strength is also frequently used to describe the resistance of tablets to the application of a compressive .Start the tablet hardness testing process as per the predetermined testing parameters, including the speed of the testing probe and the dwell time. Record the hardness value displayed by the hardness tester for each tablet tested. If required, test multiple tablets from the same batch to obtain an average hardness value. Post-Testing. Review .What is Hardness Test and Why it so important? Tablet Hardness Testing is also known as the “Crushing Strength Test“. Tablets must have a specific level of strength or hardness in order to withstand mechanical shocks during .A tablet hardness tester - sometimes also referred to as tablet breaking force tester (USP <1217>) or resistance to crushing strength tester (Ph. Eur. 2.9.8) - measures the mechanical integrity of a tablet. SOTAX tablet hardness testers with precision Dr. Schleuniger® measuring technology, standard-setting user friendliness, and robust Swiss .

A tablet hardness tester - sometimes also referred to as tablet breaking force tester (USP <1217>) or resistance to crushing strength tester (Ph. Eur. 2.9.8) - measures the mechanical integrity of a tablet. SOTAX tablet hardness testers with precision Dr. Schleuniger® measuring technology, standard-setting user friendliness, and robust Swiss .

Another common fracture test on tablets is the snap or bending test. This test is common for an oval tablet shaped like a capsule (i.e., caplet) as well as on a fairly large round tablet. . These tablet hardness tests provide a meaningful picture as to the amount of force required to fracture the solid-dose tablet. This knowledge will be .Testing of all tablet shapes, sizes, and materials. The open and accessible test area allows for simple tablet handling by the operator – and doesn’t limit the flexibility of the MT50 to measure virtually all types of tablet shapes, sizes, and materials.From standard tablet hardness tests to tensile strength and three-point flexure testing, the MT50 allows to perform different test types . hardness and/or friability testing as an in-process control (see. section 2.3). Under these circumstances, it is normally not necessary . drug product quality (e.g., chewable tablets .

tablet hardness tester types

U.S.), includes test bottle, tablets, test strips, instructions. 15-minutes to complete the water analysis testing and determine the chlorine, chloramine, iron, nitrates, hardness, and ph levels. Diamond Crystal Water Softening Products: free water hardness test kit: Tel: 800-428-4244.Hard ness Test for Tablets Teledyne LABS offers both manual and automated tablet hardness testers. Tablet hardness testing is a method of determining mechanical properties of a drug product, typically oral dosage forms such as a solid dose tablet. Tablet breaking force (commonly called tablet hardness) is a crucial characteristic in the manufacture of solid dose formulations. 4. Dissolution test: Drug should be released from tablet in a controlled and reproducible way. Weight variation, thickness & diameter: The appearance of tablet should be elegant & its weight, size & appearance should be consistent. Hardness & friability: The tablet should show sufficient mechanical strength to withstand fracture & erosion during manufacture .Tablet hardness testing is a method used to assess the mechanical strength and integrity of pharmaceutical tablets. It helps ensure that the tablets are robust enough to withstand handling, transportation, and usage without breaking or crumbling. The principles of tablet hardness testing involve the following key aspects:

The tablets are then placed between the platens of a tablet hardness tester, and test parameters, such as the rate of force application, are set according to the testing standards or specifications. During the test, the tablet hardness tester applies a controlled force to the tablet until it fractures or reaches the desired deformation level.

The variability of the results will be explored, and differences between tensile strength and tablet hardness will be discussed. 2. Thin circular discs (“round-cylindrical tablets”) . provided a sufficient number of tablets have been broken. The USP35/NF30 (2011) requires testing 6 tablets only, whereas the EP .Tablet Hardness Testing (Breaking Force) From simple hand-held units for use on the production floor, to semi-automated units for advanced analysis, Copley offers tablet hardness testers to suit every analyst’s needs. Tablet Hardness .

11. Note: • As per official standard,tablet thickness variation alloted upto (+ or -) 5% of standard value. 4.HARDNESS TEST: • This test is also known as “Crushing Strength Test”. • Tablets require a certain amount of strength, or . How To Measure Hardness in Water Softener with Test Tablets. To check if your water softener is working, you can measure the hardness with a test tablet. Fill 10mL of water from the softener into a plastic bottle. Add one .Pharmaceutical tablet hardness testing (or more correctly known as diametral/diametrical crushing strength) is a way of measuring the quality of tablets. Merlin uses tablet hardness testing to calculate the tensile strength of tablets to assess the manufacturability and compactibility of formulations.Hardness test uses a tablet reagent containing a standardised amount of EDTA with eriochrome black as indicator. The test is carried out by adding tablets one at a time to a sample of water until the colour changes from plum red to blue. The result is calculated from the number of tablets used in relation to the volume of water sample taken.

Hardness Test: For this test one of the earliest testers was the Ketan tablet hardness tester, which is a type of the Monsanto hardness tester to evaluate tablet hardness tester. The tester consists of a barrel containing a compressible spring held between two plungers. The lower plunger is placed in contact with the tablet and zero reading is .Tablet Hardness Testing Instruments Tablet hardness testing is used to test the breaking point and structural integrity of a tablet prior to storage, transportation, and handling before usage. All Pharma Test tablet hardness testing instruments meet the latest requirements of the USP and EP Pharmacopeia.

Robust automatic tablet hardness tester with two patented tablet alignment functions. Multi-batch operation in the lab and online testing with tablet press. . with robust Dr. Schleuniger® technology makes the AT50 an ideal instrument for both laboratory automation and online testing with your tablet press. Ensure comparability of results .Tablet Durometer Digital Tablet Hardness Tester Lab Tablet Hardness Testing Equipment with Test Stand 15mm Diameter Four Unit kgf/gf/N/Lbf Resolution 0.01Kgf/0.1N/0.0126F 9.00 $ 499 . 00 FREE delivery Oct 24 - 29The TBH 125 is the ERWEKA basic device for testing tablet hardness (dual-mode: “constant speed” and “constant force”), offering accuracy, robust design as well as easy and quick handling. The unit is operated via a symbol keypad which allows effortless entering of the samples number required for testing. A tablet hardness test is performed to check the strength of tablets means to know if the tablet hardness is within range or not as mentioned in BMR. One common reason to check tablet hardness is to adjust the compression force to start compression operation.

The manual tablet hardness testing instrument PTB111E / 111E-500 / 111E-800 is a dual force mode hardness test apparatus as it can be used for either linear force or linear speed increase while tablet hardness is tested. It offers a multiple point validation procedure for the built-in digital load cell. The instrument is made in strict .Tablet Hardness Testing (Breaking Force) From simple hand-held units for use on the production floor, to semi-automated units for advanced analysis, Copley offers hardness testers to suit every analyst’s needs. Tablet Hardness Tester: TBF 100i . Tablet Hardness Tester: TH3

WEB11 de out. de 2022 · Unlike many other slot machines by Booming Games, Booming Bars is a slot with a 3x3 layout. It has 10 fixed paylines and the betting range between €0.1 and €500. You can use various bonus features at your disposal to hit big wins in this slot machine. We will explain how you can do this further in this review.

hardness test for tablets|tensile strength vs hardness tablet